As a purpose-led company, we know we have a pivotal role to play in addressing the climate emergency. We consider this not only good business, but our duty to channel our technology-enabled expertise and capabilities toward benefitting people and the planet.

We work in partnership, delivering some of the most challenging, diverse and innovative projects and programs globally across multiple sectors. We integrate complex interfaces across planning, procurement and delivery to help unlock better social, environmental and economic outcomes from mega and giga projects.

For more than 30 years, Jacobs has been responsible for planning and implementing Lead and Copper Rule-related strategies which protect millions of people in the U.S. and Canada. Our work includes enhanced water quality monitoring strategies, sampling plan development, harvested pipe-scale analysis, lead service line inventories and replacement plans, corrosion control studies and the incorporation of equity and environmental justice considerations into compliance programs.

As our clients navigate the digital transformation and growing cyber risks, we have positioned ourselves at the forefront of this growth, adding digital capabilities, products and tools to serve a growing set of customers.

Sit down with our visionary team of thinkers, dreamers and doers to see what a day in the life is like.

A curated selection of some of the top-listened to and trending podcast episodes from our popular If/When podcast series, which has over 7M downloads to date.

Together with our visionary partner, PA Consulting, we're establishing our position in high end advisory services, creating a springboard to expand in high value offerings beyond the core.

At Jacobs, we're challenging today to reinvent tomorrow by solving the world's most critical problems for thriving cities, resilient environments, mission-critical outcomes, operational advancement, scientific discovery and cutting-edge manufacturing, turning abstract ideas into realities that transform the world for good. With approximately $16 billion in annual revenue and a talent force of more than 60,000, Jacobs provides a full spectrum of professional services including consulting, technical, scientific and project delivery for the government and private sector.

Jacobs. A world where you can.

As climate change threatens water security around the world, more communities are turning to water reuse as a resilient water supply solution and embracing the OneWater principle that all water has value. Jacobs has been supporting clients with water reuse programs for decades, beginning with the first applications of advanced wastewater treatment technologies in the 1960s. We provide our clients with a full range of services, from water reuse feasibility studies to design, construction and operations.

The only certainty about the future is uncertainty. Resilience is an attribute of a smarter planet, and requires planning and adapting ahead of potential threats. We help our clients survive, recover, adapt and thrive.

Jacobs is working to help clients across the United States secure federal funding for projects that make our cities and communities more connected and sustainable. Working hand-in-hand with clients from coast to coast and everywhere in between, Jacobs develops bold, innovative solutions to address the nation’s toughest challenges.

Now more than ever, we appreciate the hard work, sacrifice and dedication of the medical profession in ensuring the health and safety of our communities.

Together, we are stronger. Together, we can transform the future.

We’ve provided design-build services to the water sector for over 25 years and delivered more than 150 projects. We offer fully integrated design-build and design-build-operate capabilities to tackle the most complex water challenges and work in close collaboration with our clients.

Stories that capture our partnerships and innovative impact for a more connected, sustainable world

In 2019, nearly 40 million flights took to the sky – demonstrating the new heights modern air travel has reached since the first documented flight in history, a short 12 seconds of airtime over 120 feet completed by Orville Wright in 1903.

While certainly most well-known for that flight, Wright also is one of the masterminds behind the humble beginnings of one of the most popular technologies of the current decade – unmanned aerial vehicles (UAV), or drones. Wright and electrical engineer Charles F. Kettering developed the first functioning UAV, a 12-foot-long wooden biplane with a 15-foot-wingspan, carrying an 180-pound bomb, as part of a secret project during World War I.

According to estimates, drone technology today equates to global revenues of more than $127 million across business solutions ranging from NASA exploring drone technology to visit Saturn’s moon, Titan, to Domino’s becoming the first company to use a drone to deliver pizza. Drone technology is touted for its benefits including advancing efficiency and productivity, lowering workload and production costs, improving accuracy and service and heightening security measures across society.

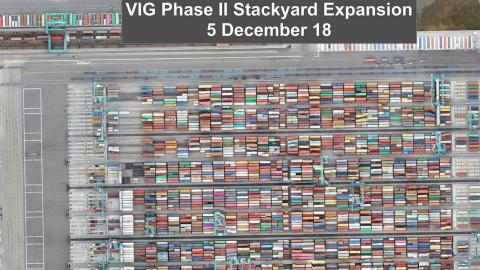

But what if we showed you how Jacobs harnessed UAV technology to deliver aerial construction progress images, reducing required data-processing time and allowing the Port of Virginia to make smart, real-time business decisions throughout a $320 million expansion project at the Virginia International Gateway?

acre expansion imaged by drone to track construction progress

more images generated using efficient drone technology to enhance coordination and heighten safety

“Unmanned aerial vehicle technology is a fast, efficient and cost-effective approach to capture project construction progress. The data that this new technology provides allows for enhanced accuracy and effectiveness for project planning and scheduling.”

Calvin Woolson, PE, CCM

Jacobs Construction Manager

With the expansion complete, four inbound truck lanes have increased the terminal’s in-gate complex capacity by 30%; doubling the size of VIG’s stack yard and boosting its container handling capability by the use of the new automated stacking cranes; expanding the rail yard capacity and increased its efficiency by the use of state of the art CRMG cranes and welcoming the arrival of the largest-ship-to-shore cranes to operate at any U.S. port.

As part of our design and construction package, Jacobs delivered aerial images of construction progress each month throughout the entire program. Because traditional methods such as airplane or helicopter imaging can be costly and require longer data processing time, we elected to use an UAV, a Phantom 4 Pro drone from Da-Jiang Innovations (DJI) to collect data aerially. We used the UAV in conjunction with the Drone Deploy application to create a flight path and get an accurate survey of the site, and used Drone Deploy and the Environmental System Research Institute’s (ESRI) Drone2Map software for data processing and image generation.

Using the drone eliminated the need for expensive manned aerial vehicle imaging and reduced the time required to process data. In fact, drones are quicker than traditional topographic survey methods and can cover approximately 200 acres in one flight, collecting millions of 3D data points and providing the opportunity to gain more data than ever before since they can capture an unobstructed view of surveyed areas. Our drone imaging takes just about a day to process and send to external stakeholders – and we can even add oblique photos, video, 3D modelling and land cover acquisition to increase its value.

Because of the UAV’s efficiency, we’re generating over 50% more images, assuring that the team has the most up-to-date information every time, enabling them to make more effective business decisions using computer-aided design and drafting (CADD) overlays to point out discrepancies saving time, money and keeping the aggressive schedule on course. For example, the use of CADD overlay drone photos can enhance coordination of the construction with ongoing port operations and other contractors on site, which mitigates costly operational disruptions, heightens safety by increasing awareness to ever changing traffic patterns on site due to construction activities, allows for clear communications to the work force which eliminates rework, improves planning of the work which decreases the duration of the project and expedites the resolution of contractor disputes (claims) as a result of its capability to cost effectively document the progress of the work.

March progress shot

June progress shot

December progress shot