The team operating the Biosolids Management Site (BMS) at the Jacobs-run Fayetteville, Arkansas, operations and maintenance project grows mixed grass, also referred to as hay, and converts wastewater treatment biosolids to fertilizer, which are marketed to local farmers. The project also applies residuals (alum-based) from a regional water treatment plant. The enriched alum waste helps prevent phosphorus runoff from the site, minimizes landfill disposal and creates a small source of revenue for the client.

Mixed-use, cattle-fed hay

To help provide the City of Fayetteville with additional revenue stream, our Jacobs team grows cattle mixed grass hay; this application also removes phosphorus from the soil. The phosphorus found in the soil is a residual from previous biosolids land application completed in the 1980s and 1990s. The grass helps with nutrient uptake. Grass is grown on approximately 540 acres of city-owned land, irrigated with reclaimed treated wastewater, harvested as hay and sold to local residents and farmers.

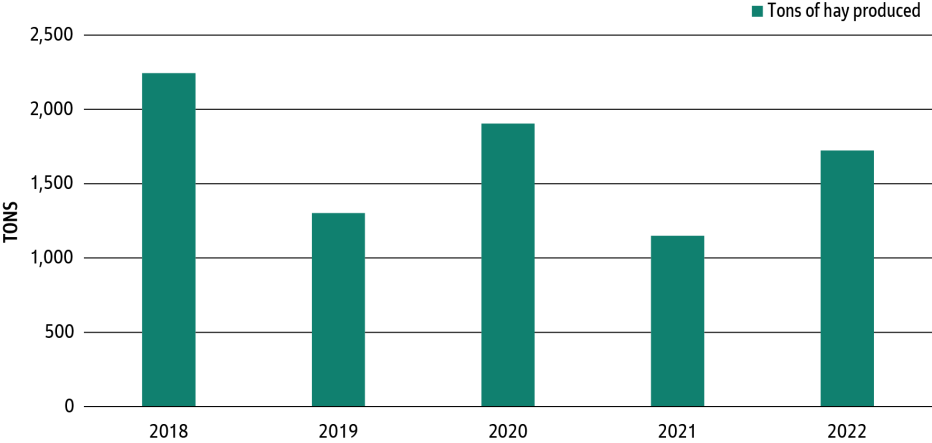

Hay production begins in early May and concludes in mid-October. In 2022, we harvested approximately 1,725 tons of mixed grass hay (roughly 4,750 bales). We harvest all forage areas at least three to four times per growing season — in 2022 we were able to harvest four times thanks to an early harvest in May.

Let’s make a deal

The team places advertisements in the local paper around mid-March each year for those interested in securing a place on the hay commitment list. In addition, an official city notice is sent to previous customers detailing when hay can be reserved. This year, due to drought conditions and the exceptional quality of the hay, the city hay sales center was not able to keep up with the calls for customers wanting to join the hay commitment list. In fact, once someone made it on the list, local residents tried to bargain with each other to obtain our hay.

New customers are allowed to purchase up to 50 tons (approximately 140 bales), and returning customers are allowed up to 200 tons (approximately 550 bales). Since more hay is requested for purchase – approximately 7,500 tons more than can be harvested – not everyone on the call-in list receives their requested order. Only those lucky enough to be one of the first 20 to 25 callers receive their full order requests.

Price is primarily determined by market supply and demand, as well as the quality of the hay. The 2022 hay sales brought $157,625 which assists with offsetting the cost of hay harvesting.

Since 2018, we have delivered $662,000 of added revenue for the city just from hay sales.

While this number is impressive, the revenue offsets the cost of the haying production by about 50%; haying product costs include labor, machinery (such as trucks, tractors, cutters and balers), insurance and other factors that come into play, reducing the revenue stream.

Practicing sustainability ahead of our time

Growing and harvesting hay in conjunction with biosolids land application isn’t a new concept. Although the initial date isn’t documented, the city started harvesting and selling hay at this site around 1983.

For the past five years, we harvested an average 1,665 tons of hay per year, which equates to approximately 4,580 4’x5’ round bales per year.

“The key to our successful hay season includes quality fertilizer application, water (reuse water) availability from the Noland Wastewater Treatment Plant, precise harvest timing and special attention the crop gets from our staff,” says Jacobs Biosolids Management Site Coordinator Peter Burrow.

Additional revenue streams via sustainability practices

Water treatment residual land application benefits the environment and our client

During our new dryer installation, the site's partially dried biosolids are sent to the local landfill. To minimize total landfill waste, the BMS team partnered with the city and the Beaver Water District to divert the water treatment residuals (WTRs) from the landfill and apply it on the available hay acreage.

The Beaver Water District, which supplies northwest Arkansas with clean drinking water, filters the residuals during its water treatment process. The Beaver Water District then trucks residuals to the BMS for land application. Thanks to diligent coordination between the city, the BMS and the Beaver Water District, water treatment residuals were only landfilled in January and part of February in 2022.

The alum-rich WTRs assist with a phosphorus binding effect and capture phosphorus in the soil. Phosphorus in the soil has positive downstream effects, as its presence enriches magnesium and calcium in the grass, enhancing its photosynthesis efficiencies and increases the grass’ nitrogen-use efficiency. This combination helps the grass grow faster and healthier, and it creates a higher-quality product.

An additional bonus of phosphorus-enriched soil is that it enhances nitrogen-use efficiency, which relates to less fertilizer requirements when compared to traditional hay growers, ultimately creating a high-quality hay product with less expense.

WTR application also generates revenue for the City. In 2022, the BMS team applied 10,118 tons of WTR to permitted application zones.

From wastewater to sludge to Class A fertilizer

Biosolids, also referred to as sludge or cake, are the byproducts of the wastewater treatment process. We dry the sludge to meet Class A fertilizer standards and sell it to local farmers at $20 per ton. We hold a call-in bi-annually on the first business day of March and the first business day of September. The process is the same as the hay call-in process. The call-in is just as competitive, and we can’t produce enough fertilizer in a six-month window to service all the customers or tonnage requested. Farmers who buy our product land apply it onto their grazing pastures and/or row crop fields.

From 2017 to 2021, we produced 13,020 tons of fertilizer.

2023 and beyond

In the 2022 growing season, the team applied 8.7 million gallons of treated effluent as irrigation to support our forage throughout the summer months. In hopes of increasing yield per acre in 2023, the team wants to apply at least 12 million gallons of treated effluent to the applicable forage areas. We anticipate land applying all WTR produced by Beaver Water District, which is expected to be close to 12,000 tons.