Jacobs. A world where you can.

As climate change threatens water security around the world, more communities are turning to water reuse as a resilient water supply solution and embracing the OneWater principle that all water has value. Jacobs has been supporting clients with water reuse programs for decades, beginning with the first applications of advanced wastewater treatment technologies in the 1960s. We provide our clients with a full range of services, from water reuse feasibility studies to design, construction and operations.

We’ve provided design-build services to the water sector for over 25 years and delivered more than 150 projects. We offer fully integrated design-build and design-build-operate capabilities to tackle the most complex water challenges and work in close collaboration with our clients.

For more than 30 years, Jacobs has been responsible for planning and implementing Lead and Copper Rule-related strategies which protect millions of people in the U.S. and Canada. Our work includes enhanced water quality monitoring strategies, sampling plan development, harvested pipe-scale analysis, lead service line inventories and replacement plans, corrosion control studies and the incorporation of equity and environmental justice considerations into compliance programs.

A curated selection of some of the top-listened to and trending podcast episodes from our popular If/When podcast series.

As a purpose-led company, we know we have a pivotal role to play in addressing the climate emergency. We consider this not only good business, but our duty to channel our technology-enabled expertise and capabilities toward benefitting people and the planet.

We work in partnership, delivering some of the most challenging, diverse and innovative projects and programs globally across multiple sectors. We integrate complex interfaces across planning, procurement and delivery to help unlock better social, environmental and economic outcomes from mega and giga projects.

As our clients navigate the digital transformation and growing cyber risks, we have positioned ourselves at the forefront of this growth, adding digital capabilities, products and tools to serve a growing set of customers.

Sit down with our visionary team of thinkers, dreamers and doers to see what a day in the life is like.

Together with our visionary partner, PA Consulting, we're establishing our position in high end advisory services, creating a springboard to expand in high value offerings beyond the core.

At Jacobs, we're challenging today to reinvent tomorrow by solving the world's most critical problems for thriving cities, resilient environments, mission-critical outcomes, operational advancement, scientific discovery and cutting-edge manufacturing, turning abstract ideas into realities that transform the world for good. With approximately $16 billion in annual revenue and a talent force of more than 60,000, Jacobs provides a full spectrum of professional services including consulting, technical, scientific and project delivery for the government and private sector.

The only certainty about the future is uncertainty. Resilience is an attribute of a smarter planet, and requires planning and adapting ahead of potential threats. We help our clients survive, recover, adapt and thrive.

Jacobs is working to help clients across the United States secure federal funding for projects that make our cities and communities more connected and sustainable. Working hand-in-hand with clients from coast to coast and everywhere in between, Jacobs develops bold, innovative solutions to address the nation’s toughest challenges.

Now more than ever, we appreciate the hard work, sacrifice and dedication of the medical profession in ensuring the health and safety of our communities.

Together, we are stronger. Together, we can transform the future.

Stories that capture our partnerships and innovative impact for a more connected, sustainable world

Stretching nearly 900 miles along the Pacific Ocean, California boasts more than 420 public beaches and close to 330 days of sunshine annually.

With all that sand, sun and salt though, don’t be surprised if your skin or hair feels a little drier. Salt water can be extremely beneficial and rejuvenating in small amounts, but experts warn that prolonged exposure can really dry out your skin because salt deposits can remain on your skin long after you shower off.

Much like our skin, infrastructure is also susceptible to its surrounding environment. Corrosion – or the breakdown or degradation of metallic materials due to an electrochemical reaction when the surrounding environment (e.g. mountain run off, lake, sea, ocean) contains organic materials (sand, gravel, clay, salt) a naturally high moisture content – can lessen the lifespan of pipes and related infrastructure considerably.

But what if we showed you how Jacobs and the San Francisco Public Utilities Commission’s (SFPUC) smart application of magnetic flux leakage technology is providing previously unattainable insight into water main health and resilience – detecting potential defects, such as corrosion, to inform data-backed asset management and capital planning?

areas of metal loss detected on SFPUC pipes using magnetic flux leakage in-line inspection technology

losses in wall thickness can now be detected using this smart application

“This technology has the potential to change the way large diameter steel water pipelines are managed throughout the world. Smart pigging technology allows owners to get a real-time vision of their assets and reduce guess work at a fraction of the cost of replacement. The benefit is to effectively determine where taxpayers’ money should be spent to efficiently repair aging infrastructure.”

Rod Jackson

Jacobs Corrosion Control Engineer

NACE International (formerly National Association of Corrosion Engineers) estimated that the U.S. spent about $276 billion annually for control and prevention in 2002 – roughly 3.1% of the country’s total GDP. With inflation and assets increasing in age since, these numbers have risen to more than $1.1 trillion in recent years and made corrosion one of the largest single U.S. expenses.

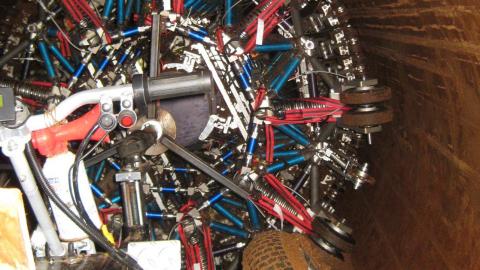

To help mitigate the issues caused by corrosion and its associated price tag, organizations perform detailed condition assessments of their pipelines, pump stations, storage tanks and corrosion control systems to gauge asset condition and reliability. Jacobs collaborated with the SFPUC and a technology company to develop a revolutionary state-of-the-art condition assessment tool to accurately access cement mortar-lined steel pipeline since none existed at the time. The new technology utilizes a non-destructive magnetic flux leakage (MFL) in-line inspection (ILI) to provide a detailed high-resolution scan.

Since the1960s, unlined steel pipelines, such as those used in the petroleum, natural gas and liquefied gas transportation markets, have been assessed using “smart pigging.” One type of smart pigging uses MFL technology which correlates changes in a magnetic field caused by pipeline defects.

While other markets can use smart pigging technologies to conduct their assessments, water pipelines typically contain lining that limited the effectiveness of MFL ILI and has kept application of this technology on for large-diameter, cement mortar-lined steel pipelines from being a reality.

Until now.

In 2007, the San Francisco Public Utilities Commission (SFPUC), began an effort to study the asset health of approximately 140 miles of large conveyance water lines (56- to 78-in. diameter) within the unique gravity-fed historic Hetch Hetchy Regional Water System which dates back to the early 1900s.

Given that smart pigging technology hadn’t been done at this scale and on large diameter mains anywhere in the world prior to Jacobs involvement with SFPUC, we weren’t just changing the way we did business – we truly were influencing how this technology could be applied for the future.

And our mission was three-fold:

“The MFL inline inspection tool makes full-length evaluation of a steel water main possible. In addition, the inspection can be performed so there is minimal disruption to environment or street traffic.”

Margaret A. Hannaford

Hetch Hetchy Water & Power San Francisco Public Utilities Commission, Division Manager

Using smart pigging technology, our testing and applied method proved capable of improving understanding of pipeline, full circumference and length, and even helped establish locations of weak points for repair and mitigation – helping SFPUC save costs for future replacement and repairs with proactive maintenance.

The ultimate result? A first-of-its-kind application of smart pig technologies for large-diameter mortar-lined pipelines that can be guided by electric tow vehicles (ETVs) and detect losses in wall thickness starting at about 20% with a high degree of accuracy.

Want more? Check out these featured industry articles: